Some drill presses and milling devices incorporate a simple belt-travel CVT process to control the pace from the chuck, such as the Jet models J-A5816 and J-A5818.[forty nine] In This method, the effective diameter of only the output shaft pulleys is constantly variable. The input pulley connected to the motor is normally preset in diameter (or often with discrete steps to allow a collection of velocity ranges).

There are a few main reasons why you may want an automobile with a CVT gearbox, but Additionally, there are some probable negatives which are worthy of being aware of.

It is the kind of conical pulley and that is mounted over the input shaft and also have interior splines meshed with the shaft splines in this kind of manner that it can shift (much too and fro) in addition to rotates Along with the input shaft. the also and fro second of the shaft over the input shaft enable it to be attainable to change equipment ratios.

This tends to make the CVT far more adaptable than its regular counterparts, allowing a sleek journey and easy acceleration Regardless of different street problems.

For this reason this stuff should be pretty sturdy in development, typically resulting in large elements. Further excess weight will likely be found in the oil reservoir and its oil load, along with the piping and valving.

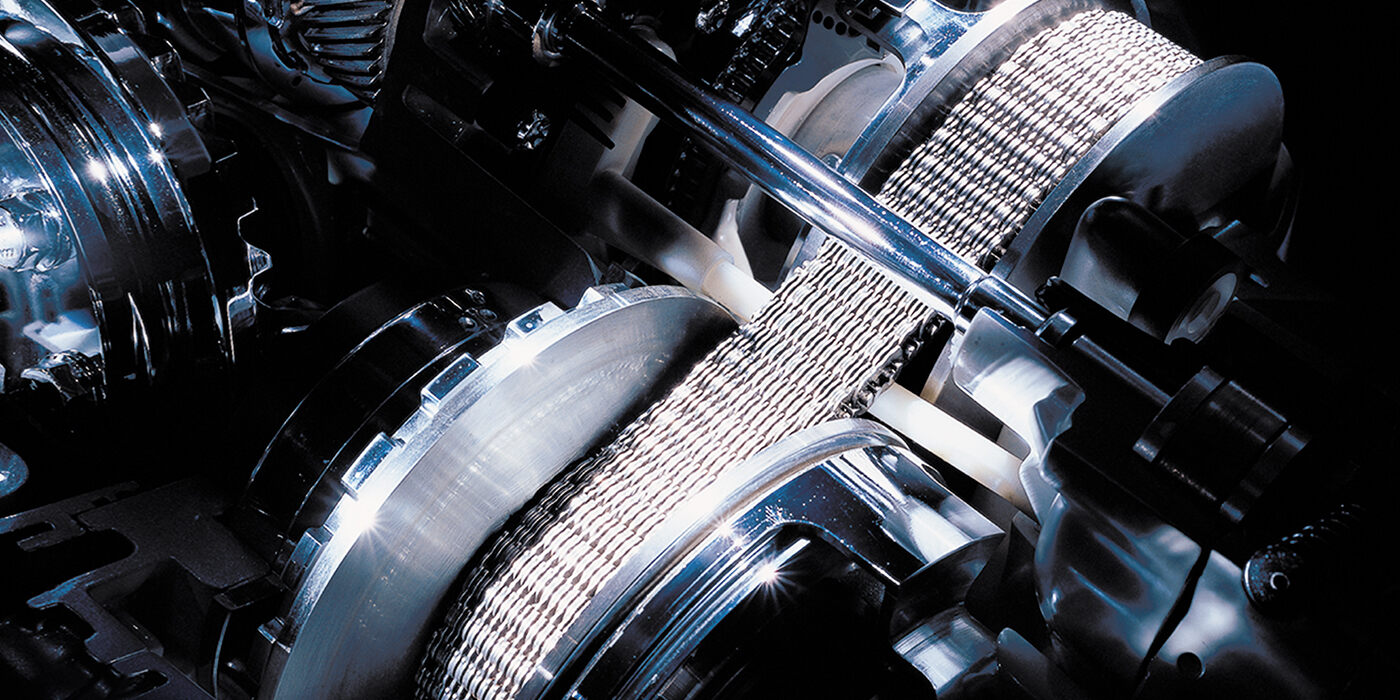

As the space between the pulleys as well as the size of the belt would not transform, the two pulleys must be altered (a single greater, another smaller sized) simultaneously to maintain the appropriate degree of rigidity about the belt. Basic CVTs combining a centrifugal push pulley that has a spring-loaded pushed pulley usually use belt tension to effect the conforming adjustments while in the pushed pulley.

The whole range of mechanical components within a CVT is scaled-down than in a typical Earth-gearset transmission. Devoid of your typical phalanx laman utama of gears and cogs, a CVT box employs a brace of adjustable conical pulleys hooked up to some steel chain or belt.

Based on the velocity on the automobile, the sides of each and every pulley shift toward or far from each other, switching the generate ratio, turning the chain into grooves between the pulleys. This mechanical simplicity ensures that points go Mistaken significantly less often.

Arbitrarily gradual crawl speeds. The possible for top torque multiplication at really low speeds permits exact vehicle motion whilst less than load.

That is an inherent good quality of all CVTs, even Individuals programmed with simulated stepped equipment. Added sound is generally unwanted in almost any auto Unless of course it is the rumble of a robust engine.

Determining and addressing these complications early can stop a lot more critical challenges and increase the life of the transmission. Normal upkeep and prompt awareness to any indications of trouble are essential for making certain the longevity and dependability of a CVT.

Driving using a CVT can offer a seamless and sleek experience around the street. Contrary to common transmissions that shift gears, a CVT provides acceleration with no interruption resulting from equipment variations.

When you’ve been purchasing for a different car or truck not long ago, you’ve unquestionably uncovered that enormous quantities of late-product motor vehicles are Geared up which has a continuously variable automatic transmission (CVT).

As vehicle engineers indicate, the motive force’s perception of sound is likewise very distinct from that of one-step automatic transmission or mechanical transmission, leading to relatively tiny acceptance.